Nylon Insert Nuts

Nylon Insert Nuts: The Complete Technical Guide & Knowledge Base

Trojan Special Fasteners Ltd is a leading UK manufacturer of precision nylon insert nuts, delivering bespoke fastening solutions across aerospace, automotive, marine, rail, and industrial engineering sectors. With decades of expertise in producing nylon insert lock nuts to exacting standards, we manufacture an extensive range of sizes in countless material and finish combinations.

What Are Nylon Insert Nuts?

Nylon insert nuts, also known as nyloc nuts, nylock nuts, aircraft lock nuts, elastic stop nuts, or nylon insert stop nuts, are hexagon nuts featuring a captive polyamide insert ring - typically manufactured from Nylon 66 polymer. This non-metallic collar is positioned within the nut body, usually in the upper portion, with an internal diameter deliberately sized smaller than the major diameter of the mating screw thread.

When the fastener is assembled, the nylon insert elastically deforms around the screw threads, creating a continuous circumferential contact that generates substantial frictional resistance. This interference fit produces a prevailing torque that prevents self-loosening caused by vibration, thermal cycling, dynamic loads, or mechanical shock whilst simultaneously providing vibration damping characteristics.

How Nylon Insert Nuts Work: The Engineering Principle

The locking mechanism relies on controlled interference between the polymer insert and the external thread of the bolt or screw. As the bolt enters the nut, the nylon ring's resilient properties allow it to expand elastically whilst maintaining constant radial pressure against the thread flanks. This creates:

- Frictional resistance across multiple thread engagement points

- Elimination of clearance between mating threads

- Continuous spring-loaded contact pressure

- Vibration isolation through polymer damping

- Self-centring alignment during assembly

Unlike purely mechanical locking devices, nylon insert nuts create a distributed load across the engaged threads rather than localised stress concentration. The polymer's viscoelastic properties absorb vibration energy, converting mechanical oscillations into heat dissipation within the molecular structure of the nylon.

Prevailing Torque Characteristics

Nylon insert nuts are classified as prevailing torque fasteners because they exhibit measurable resistance during both assembly and disassembly. The installation torque comprises two components:

- Thread friction torque - generated by the nylon insert interference

- Bearing surface torque - produced by the nut face rotating against the joint surface

The prevailing torque typically ranges from 20% to 100% of the full assembly torque, depending on thread size, material combinations, lubrication, and nylon insert compression. This characteristic necessitates the use of wrenches, spanners, or power tools for installation - hand tightening is generally insufficient for proper assembly.

Critical applications require verification that running torque remains within specified tolerances after repeated assembly cycles, ensuring the locking mechanism retains effectiveness throughout the fastener's service life.

Manufacturing Capabilities at Trojan Special Fasteners

Trojan routinely manufactures nylon insert nuts to customers' precise requirements across an extensive range of specifications:

Size Ranges:

Metric Sizes:

- M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, M15, M16, M17, M18, M20, M22, M24, M25, M26, M27, M28, M30, M32, M33, M34, M35, M36, M38, M39, M40, M42, M45, M48, M50, M52

- Available in coarse, fine, extra fine and hard-to-find pitches

Imperial and Unified Sizes:

- 1/4", 3/16", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1"

- 1.1/16", 1.1/8", 1.3/16", 1.1/4", 1.5/16", 1.3/8", 1.7/16", 1.1/2"

- 1.5/8", 1.3/4", 1.7/8", 2", 2.1/4", 2.1/2"

Thread Forms:

- BSP (British Standard Pipe)

- BSG (British Standard Gas)

- BSW (British Standard Whitworth)

- BSF (British Standard Fine)

- BSCy (British Standard Cycle)

- CEI (Cycle Engineers Institute)

- UNC, UNF, UNEF (Unified Coarse, Fine, Extra Fine)

- If we can get the thread form, we can turn it

Special Sizes:

- Non-preferred sizes available

- Intermediate sizes available

- Custom dimensions to customer specifications

Thread Variants:

- Coarse pitch threads (standard applications)

- Fine pitch threads (increased thread engagement)

- Extra fine pitch threads (thin-wall applications)

- Hard-to-find pitch combinations

- Left-hand threads (anti-loosening in rotating assemblies)

- Oversize threads (thread repair and dimensional compensation)

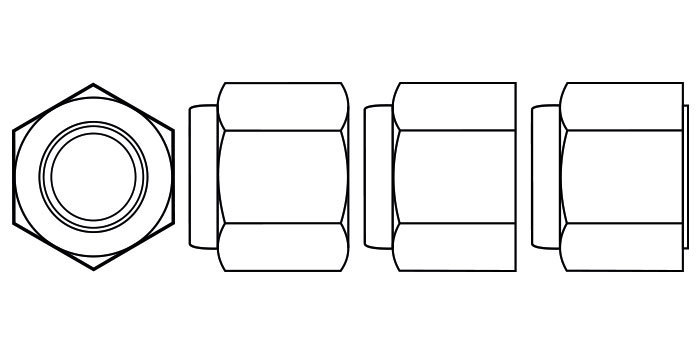

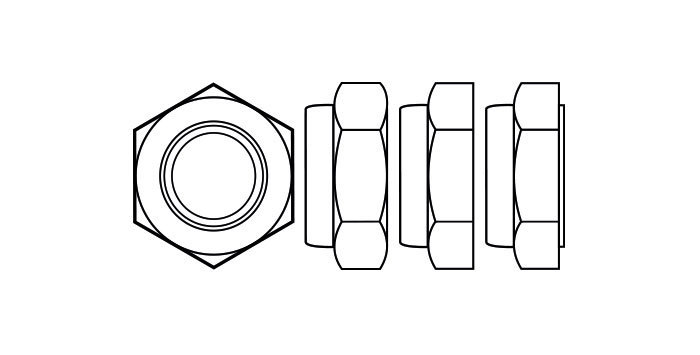

Nut Styles Available:

- Standard height nylon insert hexagon nuts

- Low-profile (thin) nylon insert nuts for restricted clearance

- Tall nylon insert nuts for extended thread engagement

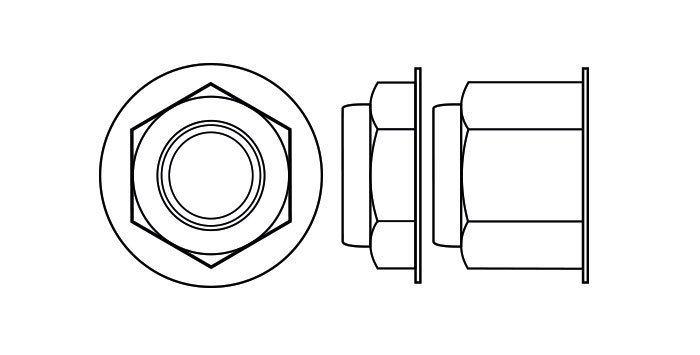

- Nylon insert flange nuts combining locking and load distribution

- All-metal hexagon body or customised nut geometries

Material Comparison for Non-Metallic Locking Inserts

| PROPERTY | PA6 | PA66 | PPS | PEEK |

|---|---|---|---|---|

| Nylon-6 | Nylon-66 | Polyphenylene Sulfide | Polyether Ether Ketone | |

| Relative Cost | £ (lowest) | ££ | £££ | £££££ (highest) |

| Typical continuous service temperature (°C) | −40 to 80–100 | −40 to 100–120 | −40 to 200–220 | −50 to 240–260 |

| Typical continuous service temperature (°F) | −40 to 176–212 | −40 to 212–248 | −40 to 392–428 | −58 to 464–500 |

| Melting or decomposition range (°C) | 210–220 | 250–260 | ≈280+ (high thermal stability) | 340–345 |

| Elastic recovery and spring-back | Good at room temperature; softens above 100 °C | Good stiffness; retains spring-back to 120 °C | Retains dimensional stability to 220 °C; moderate elasticity | High stiffness and excellent recovery to 260 °C |

| Wear resistance | Moderate | Good | Very Good | Excellent |

| Creep and stress relaxation at elevated temperature | Moderate to high creep | Lower creep than PA6 | Low creep and good preload retention | Very low creep and excellent preload retention |

| Chemical resistance | Good general resistance but attacked by strong acids; hygroscopic | Similar to PA6 with better heat resistance; hygroscopic | Very good resistance to solvents, fuels and oils; low moisture uptake | Excellent chemical resistance; very low moisture uptake |

| Interaction with metal coatings (Zinc Clear CR3, zinc flake coatings such as Geomet®) | Polymer unaffected but acid pretreatment must be avoided; lubricated coatings may reduce friction and prevailing torque | Similar to PA6; coatings on the metal can alter friction; polymer unaffected | Resistant to many plating chemistries and bake temperatures; confirm specific pretreatment and cure cycle with finisher | Fully compatible with plating and bake processes; unaffected by typical coating chemistries |

| Plating and finishing guidance | Must use acid-free pretreatment; do not pickle; drying ≤ 90 °C; if insert fitted after plating, a light zinc or acrylic spray should be applied to the exposed lip for corrosion protection | Same precautions as PA6; slightly higher temperature tolerance; drying ≤ 120 °C; spray protection recommended when insert fitted post-plating | Generally safe to plate with insert in place; confirm chemistry compatibility; drying ≤ 200 °C; zinc or lacquer spray optional | Fully stable during plating or bake; insert can remain in place; drying ≤ 250 °C; post-insert spray optional for aesthetic protection |

| Resistance to galling or seizure with steel | Low risk | Low risk | Low risk; excellent wear control | Very low risk; outstanding wear control |

| Prevailing torque performance | Very good at room temperature; torque decreases above 100 °C | Good to 120 °C; improved torque retention compared to PA6 | Consistent prevailing torque to 220 °C with correct geometry | Reliable prevailing torque to 260 °C; best retention across temperature range |

| Typical applications | Standard Nyloc nuts and general-purpose fasteners | Medium-temperature locking nuts and general-purpose fasteners | High-temperature or chemical-resistant locking nuts | Aerospace, automotive, oil & gas, and high-cycle locking applications |

General Notes to table above:

- When a fastener including its non-metallic ring is sent for plating, acid wash or pickling must be omitted for Nylon 6 and Nylon 66.

- A modified alkaline or surfactant cleaning process is recommended.

- Trojan Special Fasteners Ltd uses a controlled dedicated zinc plating process for nylon insert nuts to prevent nylon embrittlement.

- For zinc flake coatings such as Geomet®, the non-metallic ring is inserted after coating. The exposed ring area is lightly sprayed with zinc galvanising spray or clear lacquer for protection.

- PPS and PEEK rings are chemically and thermally stable under standard zinc and zinc-flake coating processes and can remain in place during plating or bake cycles.

Material & Finish Combinations

Our manufacturing flexibility enables production in virtually any commercially available material and surface finish combination:

Base Materials:

- Carbon steel (low, medium, high carbon grades)

- Alloy steels (4140, 4340, 8740 and aerospace alloys)

- Stainless steel (A2-304, A4-316, 321, 410, 17-4PH, precipitation hardening grades)

- Brass (free-cutting and corrosion-resistant: CZ121, CZ122)

- Aluminium alloys (2024, 6061, 7075 for weight-critical applications)

- Copper and copper alloys

- Phosphor bronze (PB102)

- Aluminium bronze (CA104)

- Nickel silver (NES833)

- Leaded bronze and gunmetal

Surface Finishes:

- Zinc plating (clear, yellow, black chromate)

- Hot-dip galvanising

- Phosphate coating (manganese, zinc phosphate)

- Nickel plating (bright, satin, electroless nickel)

- Chrome plating

- Passivation (stainless steel)

- Geomet and Dacromet ceramic coatings

- PTFE/Xylan dry film lubricants

- Paint and powder coating

- Self-colour (unfinished)

Nylon Insert Materials & Temperature Ratings

Standard nylon insert nuts utilise Nylon 66 (Polyamide 6,6) inserts rated for continuous operation up to 120°C (248°F). This polyamide offers excellent mechanical properties, including:

- High tensile strength and impact resistance

- Good chemical resistance to oils, fuels, and solvents

- Dimensional stability across moderate temperature ranges

- Resilience after compression (enabling limited reuse)

- Resistance to stress cracking

For elevated temperature applications between 120°C and 180°C, alternative polymer inserts are available upon request, including:

- Polyamide 4,6 (higher melting point)

- Polyimide resins (continuous use to 260°C)

- PEEK (Polyetheretherketone) for extreme temperatures

- Glass-filled nylon variants (improved dimensional stability)

For continuous service above 180°C, or applications involving extreme thermal cycling, aggressive chemicals, or ionising radiation, Trojan recommends transitioning to all-metal prevailing torque nuts such as:

- Distorted thread lock nuts (elliptical or trilobal thread forms)

- All-metal self-locking nuts with crimped threads

- Spring tab lock nuts

- Castle nuts with split pins

- Slotted nuts with wire locking

Nylon Insert Nut Standards & Specifications

Trojan Special Fasteners manufactures nylon insert nuts to numerous British, European, International, American, and military specifications:

Current British & International Standards:

- BS 1768-2 - Specification for hexagon nuts with non-metallic inserts (metric series)

- BS EN ISO 10511 - Prevailing torque type hexagon nuts with non-metallic insert (fine pitch thread)

- BS EN ISO 10512 - Prevailing torque type hexagon thin nuts with non-metallic insert

- BS EN ISO 7040 - Prevailing torque type hexagon nuts (fine pitch thread)

- BS EN ISO 7042 - Prevailing torque type hexagon nuts (coarse pitch thread)

- BS EN ISO 7719 - Prevailing torque type all-metal hexagon nuts (comparison reference)

- BS 4882 - Specification for Imperial nylon insert nuts

- BS 1769 - Specification for BA thread nylon insert nuts

American & Military Standards:

- ASME B18.16.6 - Prevailing torque type steel metric hex nuts

- ASTM F836 - Specification for style 1 hex nuts with metallic inserts

- MIL-DTL-18240 - Nuts, self-locking, 250°F

- MS17825, MS17826 - Hexagon self-locking nuts (Imperial)

- MS21044, MS21045 - Hexagon self-locking nuts (aerospace)

- NAS679, NAS1291 - Aircraft nylon insert nuts

- AN363, AN364, AN365 - Aircraft hex nuts with self-locking feature

Aerospace & Defence Standards:

- BAC 5310 - Boeing specification for self-locking nuts

- NASM17825 - Aerospace military standard self-locking nuts

- DEF STAN 02-354 - UK defence standard for aircraft fasteners

German Standards (DIN):

- DIN 985 - Prevailing torque type hexagon nuts with non-metallic insert (metric coarse)

- DIN 982 - Hexagon nuts with non-metallic insert (metric fine pitch)

- DIN 986 - Low-profile hexagon nuts with non-metallic insert

Withdrawn, Obsolete & Superseded Standards:

Many specifications historically used for nylon insert nuts have been withdrawn or superseded but remain referenced in legacy designs, maintenance manuals, and replacement part requirements. Trojan maintains manufacturing capability for fasteners to these obsolete standards:

- BS 1768-1:1989 - Superseded by BS EN ISO 7040/7042

- ISO 7040:1983 - Superseded by BS EN ISO 7040:2011

- ISO 7042:1983 - Superseded by BS EN ISO 7042:2011

- DIN 985:1979 - Superseded by BS EN ISO 7042

- DIN 982:1983 - Superseded by BS EN ISO 7040/10511

- AS 1252 - Australian standard (replaced by ISO adoption)

- AN310 - Superseded by NAS and MS standards

- MS21042, MS21043 - Superseded by MS21044/MS21045

- AIR5314 - Obsolete SAE aerospace standard

- ABG-N-007 - Legacy automotive OEM specification

- MIL-N-25027 - Cancelled military specification

International Standards from Other Regions:

- JIS B 1183 - Japanese Industrial Standard for nylon insert nuts

- GB/T 6182 - Chinese national standard (metric nylon insert nuts)

- GB/T 889.1 - Chinese hexagon nylon insert nuts

- ГОСТ Р ИСО 7042 - Russian adoption of ISO 7042

- IS 5372 - Indian standard for prevailing torque nuts

- KS B 1012 - Korean standard for self-locking nuts

- CNS 5253 - Taiwan national standard

Metric Nylon Insert Nut Thickness Comparison

This table shows the maximum overall thickness of various metric nylon insert nuts, that is, prevailing torque locking nuts with a non-metallic insert.

| Across Flat |

ASME

B18.16.3M |

ASME

B18.16.3M |

ASME

B16.16M |

ASME

B16.16M |

BS

4929-1 |

BS

4929-1 |

DIN

982 |

DIN

985 |

DIN

6294 |

DIN EN

1663 |

DIN EN

ISO 7040 |

GBT

889.2 |

GBT

6172.2 |

ISO

7040 |

ISO

7041 |

ISO

10511 |

ISO

10512 |

NFE25

-409 |

NFE25

-412 |

NFE25

-421 |

NFE25

-422 |

JIS

B1199-1 |

JIS

B1199-1 |

JIS

B1199-1 |

JIS

B1199-1 |

UNI

2733 |

UNI

7473 |

UNI

7474 |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Nominal | CLASS 5,10 | CLASS 9 | CLASS 5,10 | CLASS 9 | HIGH | NORMAL | 2016 | 2016 | 2012 | 2012 | 2012 | 2012 | 2002 | 2002 | 2002 | 2002 | Low type | Style 1 | Style 1 - Fine | Style 2 | 1975 | |||||||

| M3 | 5.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.50 | 36.00 | 4 | 4.5 | 4.5 | 3.9 | 4.5 | 3.9 | 4.5 | 3.42 | 3.9 | 4.5 | 4.4 | |||||||||||

| M3.5 | 6 | 5 | 5 | 5 | 5 | ||||||||||||||||||||||||

| M4 | 7 | 6 | 6 | 6 | 6 | 6.00 | 4.80 | 5 | 6 | 6 | 5 | 6 | 5 | 6 | 5 | 5 | 6 | 6 | 5 | ||||||||||

| M5 | 8 | 6.8 | 7.2 | 6.8 | 7.2 | 7.50 | 6.00 | 6.3 | 5 | 6.8 | 7.1 | 6.8 | 5 | 6.8 | 7.2 | 5 | 6.8 | 5 | 5 | 6.8 | 7.2 | 6.8 | 5 | ||||||

| M6 | 10 | 8 | 8.5 | 8 | 8.5 | 7.80 | 6.60 | 8 | 6 | 8 | 9.1 | 8 | 6 | 8 | 8.5 | 6 | 8 | 6 | 6 | 8 | 8.5 | 10 | 7.8 | 6 | |||||

| M7 | 11 | 8.5 | 7.5 | 9 | 9.1 | ||||||||||||||||||||||||

| M8 | 13 | 9.5 | 10.2 | 9.5 | 10.2 | 10.40 | 8.80 | 9.5 | 8 | 9.5 | 11.1 | 9.5 | 9.5 | 6.76 | 9.5 | 10.2 | 6.76 | 9.5 | 9.5 | 6.76 | 9.5 | 9.5 | 6.76 | 9.5 | 9.5 | 10.2 | 10.6 | 8 | |

| M8 | 14 | 13 | |||||||||||||||||||||||||||

| M10 | 15 | 12.5 | 13.5 | 12.5 | 13.5 | ||||||||||||||||||||||||

| M10 | 16 | 11.9 | 12.8 | 11.9 | 12.8 | 11.9 | 13.5 | 11.9 | 11.9 | 8.56 | 11.9 | 12.8 | 8.56 | 11.9 | 11.2 | 8.56 | 11.9 | 11.9 | 8.56 | 11.9 | 11.9 | 12.8 | |||||||

| M10 | 17 | 13.00 | 11.00 | 11.5 | 10 | 16 | 12.3 | 10 | |||||||||||||||||||||

| M12 | 18 | 14.9 | 16.1 | 14.9 | 16.1 | 14.9 | 16.1 | 14.9 | 14.9 | 10.23 | 14.9 | 16.1 | 10.23 | 14.9 | 14.2 | 10.23 | 14.9 | 14.9 | 10.23 | 14.9 | 14.9 | 16.1 | |||||||

| M12 | 19 | 15.60 | 13.20 | 14 | 12 | 18 | 14.8 | 12 | |||||||||||||||||||||

| M14 | 21 | 17 | 18.3 | 17 | 18.3 | 17 | 18.2 | 17 | 17 | 11.32 | 17 | 18.3 | 11.32 | 17 | 15.9 | 11.32 | 17 | 17 | 11.32 | 17 | 17 | 18.3 | |||||||

| M14 | 22 | 18.20 | 15.40 | 16 | 14 | 21 | 16.6 | 14 | |||||||||||||||||||||

| M16 | 24 | 19.1 | 20.7 | 19.1 | 20.7 | 20.80 | 17.60 | 18 | 16 | 19.1 | 19 | 19.1 | 19.1 | 12.42 | 19.1 | 20.7 | 12.42 | 19.1 | 17.8 | 12.42 | 19.1 | 19.1 | 12.42 | 19.1 | 19.1 | 20.7 | 24 | 18 | 16 |

| M18 | 27 | 20 | 18.5 | 20.6 | 26 | 21 | 18.5 | ||||||||||||||||||||||

| M20 | 30 | 22.8 | 25.1 | 22.8 | 25.1 | 26.00 | 22.00 | 22 | 20 | 22.8 | 22.7 | 22.8 | 22.8 | 14.9 | 22.8 | 25.1 | 14.9 | 22.8 | 20.7 | 14.9 | 22.8 | 22.8 | 14.9 | 22.8 | 22.8 | 25.1 | 29 | 23 | 20 |

| M22 | 32 | 28.60 | 24.20 | 25 | 22 | 24.5 | 31 | 25 | 22 | ||||||||||||||||||||

| M24 | 36 | 27.1 | 29.5 | 27.1 | 29.5 | 31.20 | 26.40 | 28 | 24 | 27.1 | 27.1 | 27.1 | 17.8 | 27.1 | 29.5 | 17.8 | 27.1 | 25 | 17.8 | 27.1 | 27.1 | 17.8 | 27.1 | 27.1 | 29.5 | 35 | 28 | 24 | |

| M27 | 41 | 32.40 | 27.00 | 27 | 29.4 | 38 | 30.8 | 27 | |||||||||||||||||||||

| M30 | 46 | 32.6 | 35.6 | 32.6 | 35.6 | 36.00 | 30.00 | 30 | 31 | 32.6 | 32.6 | 22.2 | 32.6 | 35.6 | 22.2 | 32.6 | 30.1 | 22.2 | 32.6 | 32.6 | 22.2 | 32.6 | 32.6 | 35.6 | 41 | 33.2 | 30 | ||

| M33 | 50 | 39.60 | 33.00 | 33 | 33.9 | 46 | 36 | 33 | |||||||||||||||||||||

| M36 | 55 | 38.9 | 42.6 | 38.9 | 42.6 | 43.20 | 36.00 | 36 | 37.3 | 38.9 | 38.9 | 25.5 | 38.9 | 42.6 | 25.5 | 38.9 | 36.4 | 25.5 | 38.9 | 38.9 | 25.5 | 38.9 | 38.9 | 42.6 | 49 | 40 | 36 | ||

| M39 | 60 | 39 | 40.4 | 52 | 42 | 39 | |||||||||||||||||||||||

| M42 | 65 | 42 | 43.4 | 56 | |||||||||||||||||||||||||

| M45 | 70 | 45 | 46.4 | 59 | |||||||||||||||||||||||||

| M48 | 70 | 62 | |||||||||||||||||||||||||||

| M48 | 75 | 48 | 48.4 | ||||||||||||||||||||||||||

| M52 | 75 | 68 |

We can manufacture to the following specifications:

In addition to machining nuts to your dimensions, sample or drawing, we can machine nylon insert nuts to the following specifications:

| Standard | Description |

|---|---|

| ASME/ANSI B18.16.3M | Prevailing torque hexagon nylon insert nuts |

| ASME/ANSI B18.6.6 | Prevailing torque hexagon nylon insert nuts |

| BS 4929-1 | Prevailing torque hexagon nylon insert nuts, metric threads |

| BS 4929-2 | Prevailing torque hexagon nylon insert nuts, unified threads |

| DIN 34814 | Plastic/Nylon hexagon nuts |

| DIN 6924 | Prevailing torque hexagon nylon insert nuts |

| DIN 6926 | Prevailing torque hexagon nylon insert flange nuts |

| DIN 982 | Prevailing torque hexagon thick nylon insert nuts |

| DIN 985 | Prevailing torque hexagon thin nylon insert nuts |

| EN 1663 | Prevailing torque hexagon nylon insert nuts |

| EN 1666 | Prevailing torque hexagon nylon insert nuts |

| ISO 10511 | Prevailing torque thin hexagon nylon insert nuts |

| ISO 10512 | Prevailing torque hexagon nylon insert nuts, style 1 |

| Standard | Description |

|---|---|

| ISO 10513 | Prevailing torque hexagon nylon insert nuts, style 2 |

| ISO 12125 | Prevailing torque hexagon nylon insert flange nuts |

| ISO 7040 | Prevailing torque hexagon nylon insert nuts, style 1 |

| ISO 7041 | Prevailing torque hexagon nylon insert nuts, style 2 |

| ISO 7043 | Prevailing torque hexagon nylon insert flange nuts |

| NF E25-409 | Prevailing torque hexagon nylon insert nuts, style 1 |

| NF E25-412 | Prevailing torque hexagon nylon insert nuts |

| NF E25-413 | Prevailing torque hexagon nylon insert flange nuts |

| NF E25-506 | Prevailing torque hexagon nylon insert flange nuts |

| UNI 2733 | Prevailing torque thick hexagon nylon insert nuts |

| UNI 7473 | Prevailing torque short hexagon nylon insert nuts |

| UNI 7474 | Prevailing torque thick hexagon nylon insert nuts |

Additionally, we can manufacture:

- NU Series nylon insert lock nuts

- NTU Series nylon insert lock nuts

- NTE Series nylon insert lock nuts

- NE Series nylon insert lock nuts

Applications Across Industries

Nylon insert nuts provide reliable locking performance across diverse sectors:

Aerospace & Defence:

- Aircraft structural assemblies

- Engine mounting hardware

- Avionics equipment

- Landing gear components

- Missile and munitions assembly

- UAV and drone construction

Automotive & Motorsport:

- Suspension systems

- Exhaust manifolds and systems

- Gearbox assemblies

- Brake callipers

- Engine components

- Roll cage mounting

- Racing car safety-critical fasteners

Marine & Offshore:

- Propulsion systems

- Deck equipment

- Navigation electronics

- Galley and accommodation fittings

- Outboard motor mounting

- Sailing yacht rigging

Rail & Transport:

- Bogie assemblies

- Coupling mechanisms

- Interior fittings

- Door mechanisms

- Electrical junction boxes

- Signalling equipment

Industrial & Manufacturing:

- Vibrating machinery

- Conveyor systems

- Robotic equipment

- Pumps and compressors

- HVAC installations

- Material handling equipment

Construction & Infrastructure:

- Steel framework connections

- Bridge components

- Scaffolding systems

- Lifting equipment

- Temporary works

Electronics & Telecommunications:

- Rack-mounted equipment

- Antenna assemblies

- Outdoor enclosures

- Vibration-sensitive instruments

Nylon Insert and Non-Metallic Insert Nut Standards

This table shows current and withdrawn standards for flange and collar nuts in various forms. It is not an exhaustive list. Trojan Special Fasteners Limited can manufacture many of these types.

| STANDARD | YEAR | DESCRIPTION | SIZE RANGE | STATUS | SUPERSEDED BY |

|---|---|---|---|---|---|

| AECMA EN 2549 | 2001 | Aerospace: Hex flange nuts, self-locking | M3 - M12 | Current | |

| ANSI B18.16.3M | 1998 | Metric Prevailing Torque Hex Nuts (Dim.) | M5 - M36 | Withdrawn | ASME B18.16M |

| AS/NZS 1112.4 | 2015 | Aus/NZ: Prevailing torque hex nuts | M5 - M36 | Current | |

| ASME B18.16.6 | 2017 | Nylon Insert Locknuts (Inch: NM, NE, NTE) | #2 - 1-1/2" | Current | |

| ASME B18.16M | 2004 | Metric Prevailing Torque Hex/Flange Nuts | M3 - M36 | Withdrawn | ISO 7040 / 7043 |

| BS 4929-1 | 1973 | Metric prevailing torque nuts | M3 - M36 | Withdrawn | BS EN ISO 7040 |

| BS 4929-2 | 1973 | Unified Inch prevailing torque nuts | 1/4" - 1-1/2" | Withdrawn | ASME B18.16.6 |

| BS EN 1663 | 1998 | Prevailing torque hex flange nuts (Nylon) | M5 - M20 | Withdrawn | BS EN ISO 7043 |

| BS EN ISO 7040 | 2012 | British adoption of ISO 7040 | M3 - M36 | Current | |

| CSN 02 1492 | 1985 | Czech: Hex nuts with Polyamide insert | M3 - M36 | Withdrawn | CSN EN ISO 7040 |

| DIN 982 | 1987 | Prevailing torque hex nuts (High/Heavy) | M5 - M24 | Withdrawn | ISO 7041 |

| DIN 985 | 1987 | Prevailing torque hex nuts (Thin/Std) | M3 - M48 | Withdrawn | ISO 10511 |

| DIN 986 | 1987 | Prevailing torque hex domed cap nuts | M4 - M20 | Current | |

| DIN 6924 | 1983 | Hexagon nuts with non-metallic insert | M3 - M48 | Withdrawn | ISO 7040 |

| DIN 6926 | 1983 | Hexagon flange nuts with non-metallic insert | M5 - M16 | Withdrawn | ISO 7043 |

| DIN EN 1663 | 1998 | Prevailing torque hex flange nuts (Nylon) | M5 - M20 | Withdrawn | DIN EN ISO 7043 |

| DIN EN ISO 7040 | 2013 | German adoption of ISO 7040 | M3 - M36 | Current | |

| GB/T 6172.2 | 2016 | Chinese Hexagon thin nuts, non-metallic | M3 - M36 | Current | |

| GB/T 6182 | 2016 | Chinese Hex nuts, style 2, non-metallic | M5 - M36 | Current | |

| GB/T 6183.1 | 2016 | Chinese Hexagon flange nuts, non-metallic | M5 - M20 | Current | |

| GB/T 889.1 | 2015 | Chinese Hex nuts, style 1, coarse thread | M3 - M36 | Current | |

| GB/T 889.2 | 2016 | Chinese Hex nuts, style 1, fine pitch | M8 - M36 | Current | |

| GOST R 50271 | 1992 | Russia: Self-locking nuts with insert | M3 - M36 | Current | |

| IFI 100/107 | 2002 | Prevailing-Torque Type Steel Hex/Flange | #4 - 1-1/2" | Withdrawn | ASME B18.16.6 |

| IS 7002 | 2005 | Indian Standard: Prevailing torque hex nuts | M3 - M36 | Current | |

| ISO 7040 | 2012 | Hex nuts, style 1, non-metallic insert | M3 - M36 | Current | |

| ISO 7041 | 2012 | Hex nuts, style 2, non-metallic insert | M5 - M36 | Current | |

| ISO 7043 | 2012 | Hexagon flange nuts, style 2, non-metallic | M5 - M20 | Current | |

| ISO 10511 | 2012 | Hexagon thin nuts, non-metallic insert | M3 - M36 | Current | |

| ISO 10512 | 2012 | Hex nuts, style 1, fine pitch, non-metallic | M8 - M36 | Current | |

| ISO 10513 | 2012 | Hex nuts, style 2, fine pitch, non-metallic | M8 - M36 | Current | |

| ISO 12125 | 2012 | Hex flange nuts, high, fine pitch, non-metallic | M8 - M20 | Current | |

| ISO 12126 | 2012 | Hex flange nuts, style 2, fine, non-metallic | M8 - M20 | Current | |

| JASO F108 | 1990 | Japan Automotive: Prevailing torque nuts | M6 - M16 | Current | |

| JIS B 1199-1 | 2001 | Japan: Hex nuts (ISO Style), non-metallic | M3 - M36 | Current | |

| JIS B 1199-2 | 2001 | Japan: Hex nuts (Original), non-metallic | M3 - M36 | Current | |

| KS B 1044 | 2018 | Korea: Hex nuts, style 1, non-metallic insert | M3 - M36 | Current | |

| MS 21044 | 1990 | Military Standard: Non-metallic insert | #4 - 1-1/2" | Withdrawn | NASM 21044 |

| NASM 21044 | 2002 | Aerospace: Self-locking, Regular Height | #4 - 1-1/4" | Current | |

| NASM 21083 | 2002 | Aerospace: Self-locking, Low Height | #4 - 1-1/4" | Current | |

| NF E 25-412 | 1997 | France: Hexagon thin nuts, non-metallic | M3 - M36 | Withdrawn | ISO 10511 |

| NF E 25-413 | 1998 | France: Hexagon flange nuts, non-metallic | M5 - M20 | Withdrawn | ISO 7043 |

| ÖNORM EN ISO 7040 | 2013 | Austria: Hex nuts, style 1, non-metallic | M3 - M36 | Current | |

| ÖNORM M 5275 | 1986 | Austria: Self-locking hex nuts with insert | M3 - M36 | Withdrawn | EN ISO 7040 |

| PN-M-82463 | 1985 | Poland: Hex nuts with non-metallic insert | M3 - M48 | Withdrawn | PN-EN ISO 7040 |

| SAE J995 | 1999 | Mechanical/Material Requirements for Nuts | #4 - 1-1/2" | Current | |

| SN 212745 | 1990 | Switzerland: Hex nuts, non-metallic insert | M3 - M36 | Withdrawn | SN EN ISO 7040 |

| SNV 21274 | 1980 | Swiss (SNV): Self-locking nuts with insert | M4 - M24 | Withdrawn | SN 212745 |

| STAS 11094 | 1978 | Romania: Prevailing torque hex nuts | M3 - M36 | Withdrawn | SR EN ISO 7040 |

| UNE-EN ISO 7040 | 2013 | Spain: Hex nuts, style 1, non-metallic | M3 - M36 | Current | |

| UNI 2733 | 1944 | Italy: Castle nuts (Industrial insert types) | M6 - M52 | Withdrawn | |

| UNI 7473 | 1975 | Italy: Self-locking hex nuts (Standard) | M3 - M36 | Withdrawn | ISO 7040 |

| UNI 7474 | 1975 | Italy: Self-locking hex nuts (Thin) | M3 - M36 | Withdrawn | ISO 10511 |

| VSM 13915 | 1975 | Switzerland: Prevailing torque nuts | M3 - M30 | Withdrawn | SN EN ISO 7040 |

Reusability & Service Life Considerations

The question of whether nylon insert nuts can or should be reused generates considerable debate within the engineering community. The answer depends critically on application severity, consequence of failure, and operational economics.

The Case for Limited Reuse:

Certain nylon insert designs, particularly those conforming to aerospace specifications, feature robust polymer collars engineered to withstand multiple assembly cycles without permanent deformation. Laboratory testing demonstrates that properly designed inserts can maintain prevailing torque values within acceptable ranges through 5-15 installation/removal cycles when:

- The fastener has not been subjected to temperature extremes

- Thread damage or galling has not occurred

- Chemical exposure has been minimal

- The original prevailing torque measurement remains within specification

- The application is non-critical

Various aerospace and military standards explicitly require self-locking nuts to maintain running torque after a specified number of assembly cycles without preload, recognising controlled reuse in maintenance scenarios.

The Case Against Reuse:

Despite theoretical reusability, several degradation mechanisms compromise nylon insert performance during service:

Mechanical Degradation:

- Compressive set - permanent deformation from sustained thread pressure

- Creep - time-dependent dimensional change under constant load

- Fatigue - micro-crack propagation from cyclic thread engagement

- Abrasive wear - material removal from repeated installations

Environmental Degradation:

- Thermal aging - polymer chain scission from elevated temperatures

- UV radiation - photochemical degradation (outdoor applications)

- Chemical attack - plasticiser migration, swelling, or embrittlement

- Moisture absorption - dimensional change and property reduction

- Stress corrosion - environmental stress cracking

Uncertainty Factors:

- Unknown service history (time, temperature, load cycles)

- Unquantified chemical exposure

- Invisible internal damage

- Indeterminate remaining service life

Trojan's Professional Recommendation:

For critical applications - those where fastener failure creates safety hazards, catastrophic equipment damage, or mission-critical system loss - Trojan Special Fasteners categorically recommends against reuse. The modest cost of replacement fasteners represents negligible expense compared to failure consequences.

Nylon insert nuts are precision-engineered consumable components, not permanent hardware. Their relatively low unit cost and ease of replacement eliminate economic justification for reuse in critical assemblies.

For non-critical applications where failure poses minimal risk, reuse may be acceptable provided:

- Running torque is verified with a calibrated torque wrench

- Measured prevailing torque falls within original specification limits

- Visual inspection reveals no thread damage, nylon deterioration, or contamination

- Service history is documented and within conservative limits

- The decision is approved by qualified engineering authority

Companies employing formal fastener reuse policies typically establish prevailing torque envelope limits (minimum and maximum acceptable values) and mandate replacement when measurements fall outside these boundaries or after a specified number of cycles, whichever occurs first.

Advantages of Nylon Insert Nuts

- Vibration resistance - superior locking performance in dynamic environments

- Reusable - limited reinstallation capability (unlike adhesive thread lockers)

- No preparation required - no primers, cleaners, or cure time

- Tamper evidence - visible indication if disturbed

- Corrosion isolation - nylon prevents galvanic corrosion between dissimilar metals

- Vibration damping - polymer absorbs oscillatory energy

- Wide availability - extensive size and material ranges

- Proven performance - decades of field service data

- Cost-effective - economical compared to specialised locking fasteners

- Temperature tolerance - suitable for most industrial environments

Limitations & Considerations

- Temperature ceiling - standard nylon limited to 120°C continuous

- Installation torque - requires tools; cannot be hand-tightened

- One-direction loading - primarily effective in tension applications

- Chemical compatibility - certain solvents or fuels may degrade nylon

- Overtightening risk - excessive torque can extrude or damage insert

- Inspection difficulty - polymer condition not visible when assembled

- Thread damage - cross-threading can compromise locking effectiveness

- Electrical insulation - nylon creates electrical discontinuity (may be advantage or disadvantage)

Installation Best Practices

Thread Preparation:

- Ensure mating threads are clean, undamaged, and free from burrs

- Remove any thread cutting chips, swarf, or contamination

- Verify thread class and pitch match nut specification

- Check for galling on stainless steel threads (use anti-seize if specified)

Installation Technique:

- Start nut by hand to verify proper thread engagement

- Use wrenches or sockets - never impact tools for critical applications

- Apply steady, continuous torque without jolting or hammering

- Observe torque specification and tightening sequence

- For critical joints, measure and record installation torque

Torque Values:

- Installation torque includes both prevailing torque and clamping force

- Typical prevailing torque adds 20-100% to assembly torque requirement

- Consult application engineering or OEM specifications

- Never exceed maximum torque for thread size and material

- Consider torque-angle tightening for precision applications

Common Installation Errors:

- Cross-threading during initial engagement

- Overtightening causing nylon extrusion

- Using impact wrenches (damages polymer insert)

- Reusing nuts without torque verification

- Installing on damaged threads

- Failure to observe tightening sequence in multi-bolt patterns

Quality Assurance & Testing

Trojan Special Fasteners employs rigorous quality protocols ensuring every nylon insert nut meets specification requirements:

Dimensional Verification:

- Thread pitch, diameter, and class measurement

- Across-flats width and height

- Concentricity and perpendicularity

- Insert depth and alignment

Mechanical Testing:

- Proof load testing (verifying tensile strength)

- Prevailing torque measurement (on-torque, running torque)

- Thread engagement depth

- Seating torque verification

Material Analysis:

- Chemical composition verification (spectroscopy)

- Hardness testing (Rockwell, Brinell, or Vickers)

- Metallurgical inspection (where specified)

- Coating thickness measurement

Insert Quality:

- Polymer material verification

- Insert retention (pullout or push-out force)

- Temperature performance validation

- Chemical resistance (when specified)

Frequently Asked Questions (FAQ) About Nylon Insert Nuts

Section 1: General Understanding & Terminology

1. What is the difference between a nyloc nut and a nylock nut?

There is no technical difference - these are simply alternate spellings of the same product type. Both terms refer to nylon insert lock nuts. The variation arose from different manufacturers' trademarking attempts. "Nyloc" was a prominent early brand name that became genericised. The technically correct term is "nylon insert lock nut" or "nylon insert prevailing torque nut," but nyloc, nylock, elastic stop nut, and aircraft lock nut are all widely used synonymously throughout the industry.

2. Are nylon insert nuts the same as self-locking nuts?

Nylon insert nuts are one specific type within the broader category of self-locking nuts. Self-locking nuts encompass any nut design that resists loosening without external locking devices (such as lock washers, cotter pins, or safety wire). This includes all-metal distorted thread nuts, elliptical top lock nuts, centre lock nuts with crimped inserts, and polymer insert nuts. Nylon insert nuts represent the most common self-locking nut type for moderate temperature applications due to their reliability and cost-effectiveness.

3. What does "prevailing torque" mean?

Prevailing torque is the measurable rotational resistance experienced when turning a nut onto a bolt before the nut contacts the bearing surface (the "running torque") and after it lifts off the bearing surface during removal (the "breakaway torque"). This resistance, typically ranging from 0.5 to 5 Nm depending on size, indicates the locking mechanism is functioning. Specifications establish minimum and maximum prevailing torque values that must be maintained throughout the nut's service life to ensure reliable locking performance.

4. Why are nylon insert nuts called aircraft lock nuts?

Early aerospace applications drove nylon insert nut development in the 1940s-1950s when aircraft designers sought reliable vibration-resistant fasteners for safety-critical assemblies. Military and commercial aircraft subjected fasteners to intense vibration, temperature variation, and dynamic loading. Nylon insert nuts proved exceptionally effective, earning widespread adoption throughout aerospace industries. Military specifications (MS, NAS, AN) formalised their use, cementing the "aircraft lock nut" designation. Today they're equally common in automotive, marine, and industrial applications.

5. What is Nylon 66 and why is it used?

Nylon 66 (Polyamide 6,6) is a semi-crystalline thermoplastic polymer formed through polycondensation of hexamethylene diamine and adipic acid. Its molecular structure provides excellent mechanical properties including high tensile strength (70-85 MPa), good impact resistance, dimensional stability across moderate temperatures, and resilience after compression - ideal characteristics for a locking insert. The material designation "66" refers to six carbon atoms in each of the two molecular precursors. Nylon 66 offers superior temperature resistance compared to Nylon 6, making it the preferred polymer for prevailing torque applications.

6. Can nylon insert nuts be used underwater or in marine environments?

Yes, nylon insert nuts perform excellently in marine environments when manufactured from appropriate corrosion-resistant materials. For saltwater applications, specify stainless steel (A4-316) or bronze nuts with nylon inserts. The polyamide insert absorbs minimal moisture (approximately 1-2% water absorption at saturation), causing negligible dimensional change. Nylon actually provides beneficial galvanic isolation between dissimilar metal threads, preventing electrolytic corrosion. Marine-grade nylon inserts resist most marine fuels, lubricants, and bilge contaminants. Trojan manufactures extensive ranges of marine-spec nylon insert nuts for yacht builders, commercial vessels, and offshore installations.

7. What's the difference between a nylon insert nut and a nylon lock nut?

These terms are interchangeable - both refer to the same product. The fastener industry uses various nomenclature including nylon insert nut, nylon lock nut, nylon locking nut, nylon insert lock nut, and elastic stop nut. All describe a hexagon nut containing a captive nylon collar that creates prevailing torque against bolt threads. Consistency in terminology isn't universal, but "nylon insert nut" or "nylon insert lock nut" represents the most technically precise description used in international standards such as BS EN ISO 7042.

8. How are nylon insert nuts different from lock washers?

These represent fundamentally different locking philosophies. Lock washers (split washers, spring washers, or toothed washers) attempt to maintain bolt tension through spring action or bite into adjacent surfaces, but numerous studies demonstrate they provide minimal vibration resistance. Nylon insert nuts create continuous frictional interference between threads throughout the engaged length, physically preventing nut rotation even when joint preload relaxes. Testing consistently shows nylon insert nuts dramatically outperform lock washers in vibration testing. For critical applications requiring reliable anti-loosening performance, nylon insert nuts are categorically superior.

Section 2: Technical Specifications & Standards

9. What standards govern nylon insert nut manufacturing?

Multiple international standards specify dimensional, mechanical, and performance requirements. Primary British/European standards include BS EN ISO 7042 (metric coarse), BS EN ISO 7040 (metric fine), BS EN ISO 10511/10512 (thin nuts), and BS 1768 (Imperial sizes). American standards include ASME B18.16.6 and ASTM F836. Military/aerospace specifications include MIL-DTL-18240, MS17825/17826, and NAS679. German DIN 985/982/986 remain widely referenced despite ISO supersession. Each standard prescribes specific dimensions, tolerances, thread classes, material grades, prevailing torque ranges, proof loads, and testing protocols.

10. What is the difference between ISO 7040 and ISO 7042?

ISO 7042 specifies nylon insert nuts for metric coarse pitch threads (standard thread pitch for each diameter), whilst ISO 7040 covers metric fine pitch threads (closer thread spacing). Fine pitch threads provide greater thread engagement per unit length, useful in thin-wall applications or when maximum thread strength is required. Both standards define identical hexagon across-flats dimensions and nut heights for corresponding thread sizes but differ in thread pitch specifications. For example, M10 ISO 7042 specifies 1.5mm pitch whilst M10 ISO 7040 covers 1.25mm and 1.0mm fine pitches.

11. Are DIN 985 and ISO 7042 interchangeable?

Functionally yes, dimensionally yes with minor tolerance variations. DIN 985 was the original German national standard for metric coarse nylon insert nuts, later superseded by ISO 7042 which harmonised dimensions across European nations. Current BS EN ISO 7042 represents the British adoption of this international standard. Nuts manufactured to DIN 985 typically meet ISO 7042 requirements and vice versa. However, formal approval or aerospace applications may require explicit specification compliance documentation. When substituting, verify that tolerance bands, material grades, and prevailing torque values satisfy application requirements.

12. What thread classes are used for nylon insert nuts?

Most nylon insert nuts employ Class 6H internal threads (ISO metric) or Class 2B threads (Unified), representing free-running fits with moderate clearance. These thread classes permit easy nut starting whilst the nylon insert provides locking action. Tighter thread classes would increase installation torque excessively and risk thread galling. Aerospace applications may specify Class 3B threads for precision fit. The external thread (bolt or screw) typically uses Class 6g (ISO) or Class 2A (Unified). Left-hand thread variants maintain the same class designations with opposite helix direction.

13. What are the material grade requirements for structural applications?

Grade 8 (metric) or Grade 5 (Imperial) represents the minimum specification for structural steel applications. Grade 8 requires minimum 800 MPa tensile strength with 640 MPa proof load. High-strength applications demand Grade 10 (1040 MPa) or Grade 12 (1220 MPa) materials. Stainless steel structural applications typically specify A4-70 or A4-80 grades (700 or 800 MPa). Aerospace applications often require custom alloy specifications with full traceability and material certification. Trojan maintains extensive material inventory across standard and high-strength grades.

14. Do nylon insert nuts require specific torque specifications?

Yes. Installation torque for nylon insert nuts must account for both the prevailing torque (locking resistance) and the desired clamp load. The total installation torque typically runs 20-100% higher than equivalent plain nuts. Standard torque tables must be adjusted upward, or application-specific testing performed to establish correct values. Over-torquing risks damaging the nylon insert or stripping threads; under-torquing fails to achieve adequate clamp load. Critical applications require calibrated torque wrenches and documented torque values. Trojan can provide application engineering support to establish appropriate torque specifications for specific assemblies.

15. What is the proof load for a nylon insert nut?

Proof load represents the maximum tensile stress a nut must withstand without thread stripping or permanent deformation. For metric Grade 8 nuts, proof load equals 640 MPa times the stress area. For example, an M10 Grade 8 nylon insert nut must support approximately 46.5 kN (4,750 kgf) without failure. The nylon insert does not significantly affect proof load capacity - the metallic thread engagement determines strength. Testing involves threading the nut onto a mandrel and applying specified tensile load; the nut must not strip or show permanent deformation. Proof loads are tabulated in relevant standards for each thread size and material grade.

Section 3: Materials, Finishes & Coatings

16. What material should I specify for outdoor applications?

For outdoor exposure combining moisture, UV radiation, and temperature cycling, specify A4-316 stainless steel (marine-grade austenitic stainless) with passivated finish. This material provides excellent atmospheric corrosion resistance without coating dependence. For high-strength outdoor applications where stainless steel is insufficient, use carbon steel or alloy steel with hot-dip galvanising (85 microns minimum) or Geomet/Dacromet ceramic coating. Avoid electroplated zinc in aggressive outdoor environments - it provides limited protection. The nylon insert itself demonstrates good UV resistance, though prolonged direct sunlight exposure may cause slight embrittlement over years.

17. Are stainless steel nylon insert nuts magnetic?

Depends entirely on the stainless steel grade. Austenitic grades (A2-304, A4-316) are non-magnetic in annealed condition, useful where magnetic interference must be avoided (medical equipment, instrumentation, compass proximity). However, cold working during thread forming can induce slight magnetism. Martensitic stainless grades (410, 420) and precipitation-hardening grades (17-4PH) are magnetic. If non-magnetic behaviour is critical, specify A4-316 in annealed condition and verify with testing. Some applications actually require magnetic fasteners for retrieval purposes - inform Trojan of your specific magnetic property requirements.

18. Can you supply nylon insert nuts in bronze or specialist copper alloys?

Yes. Trojan manufactures nylon insert nuts in various bronze and copper alloy grades including phosphor bronze (PB102), aluminium bronze (CA104), nickel silver (NES833), and other specialist materials. These materials offer excellent corrosion resistance, good electrical and thermal conductivity, and non-sparking properties important for hazardous environments. Bronze nuts are particularly popular in marine applications, electrical engineering, and industries requiring non-magnetic, non-sparking fasteners. Lead times may be extended for specialist materials depending on availability.

19. What is the difference between zinc plating and hot-dip galvanising?

Zinc plating (electroplating) deposits 5-25 micron zinc layers through electrolytic process, providing decorative finish and moderate corrosion protection (typically 200-500 hours salt spray resistance). Hot-dip galvanising immerses parts in molten zinc at 450°C, creating 50-150 micron metallurgically-bonded coating offering 1000+ hours salt spray protection. Galvanised nuts have rougher appearance, thicker coating (affecting thread dimensions), and superior longevity. Galvanising suits outdoor structural applications; zinc plating suits automotive and general industrial use. For nylon insert nuts, verify the galvanising temperature profile doesn't degrade the polymer insert - Trojan uses controlled processes preserving insert integrity.

20. What is cadmium plating and when is it specified?

Cadmium plating provides exceptional corrosion protection with excellent electrical conductivity and low friction characteristics, explaining its historical aerospace dominance. However, cadmium is highly toxic, environmentally hazardous, and increasingly restricted under RoHS and REACH regulations. It remains permissible in aerospace and defence applications where safety-critical performance justifies use. Cadmium plating provides superior performance in marine atmospheres compared to zinc. If your application specifies cadmium-plated fasteners (common in legacy aerospace designs), Trojan can supply to MIL-DTL-870 specifications, though we recommend exploring zinc-nickel or IVD aluminium alternatives where permissible.

21. What does passivation do for stainless steel nuts?

Passivation chemically removes free iron contamination from stainless steel surfaces and promotes formation of a dense chromium oxide protective layer. Manufacturing processes (machining, thread rolling) can embed steel tool particles onto stainless parts, creating corrosion initiation sites. Passivation using nitric or citric acid baths dissolves these contaminants whilst leaving the chromium-rich stainless steel matrix intact. The resulting chromium oxide film provides the corrosion resistance that defines stainless steel. All Trojan stainless steel nylon insert nuts receive passivation treatment per ASTM A967 unless otherwise specified, ensuring maximum corrosion performance.

22. Can nylon insert nuts be painted or powder coated?

Yes, but with important considerations. The nylon insert must be protected during the coating process to prevent polymer degradation from heat or chemical exposure. Powder coating typically requires 180-200°C curing temperatures, potentially damaging standard Nylon 66 inserts rated to 120°C continuous. Solutions include: masking the internal threads and insert during coating; installing inserts after coating (requires post-coating assembly capability); using high-temperature polymer inserts; or applying liquid paint with lower cure temperatures. For aesthetic matching in assemblies, Trojan can coordinate coating application ensuring the locking function remains uncompromised.

Section 4: Temperature Performance & Environmental Resistance

23. What is the maximum temperature for nylon insert nuts?

Standard Nylon 66 inserts provide reliable locking function for continuous operation up to 120°C (248°F). Short-term exposure to 150°C is generally acceptable for limited durations. Beyond 120°C continuous, the nylon begins softening, reducing prevailing torque and potentially causing creep or dimensional change. For applications between 120-180°C, Trojan can supply nuts with high-temperature polyamide or polyimide inserts. Above 180°C, transition to all-metal prevailing torque nuts (distorted thread, crimped collar, or spring tab designs) becomes necessary. Always consult application engineering when operating temperatures approach insert material limits.

24. Do nylon insert nuts work in freezing temperatures?

Yes, excellent performance in cold environments. Nylon 66 actually becomes stronger and stiffer at reduced temperatures, increasing prevailing torque slightly. Testing demonstrates reliable function to -55°C and below. Cold temperature embrittlement is not a concern within normal industrial temperature ranges (-40°C to +120°C). Arctic, Antarctic, and cryogenic applications routinely employ nylon insert nuts successfully. The greater challenge in extreme cold involves differential thermal contraction between the nut, bolt, and joint materials - ensure adequate preload to maintain clamp force through thermal cycling. Trojan has supplied nylon insert nuts for polar research equipment, refrigeration, and LNG applications.

25. What happens if a nylon insert nut gets too hot during service?

Excessive temperature exposure degrades the nylon insert through thermal aging processes. Initial symptoms include reduced prevailing torque as the polymer softens. Prolonged overheating causes molecular chain scission, irreversibly destroying the polymer's mechanical properties. The insert may discolour (yellowing or browning), become brittle, or completely lose resilience. Once thermally damaged, the nut cannot recover - replacement is mandatory. Applications involving periodic thermal spikes (engine components, brake systems) require careful evaluation. If you suspect temperature-related degradation, measure prevailing torque - values below specification minimums indicate the nut should be replaced.

26. Are nylon insert nuts resistant to oil and fuel?

Yes, Nylon 66 demonstrates good chemical resistance to most petroleum-based oils, greases, hydraulic fluids, and fuels. Automotive engine oil, transmission fluid, diesel fuel, kerosene, and hydraulic oil generally cause no significant degradation. However, certain aromatic hydrocarbons and aggressive solvents can swell or weaken nylon over extended exposure. Gasoline containing high aromatic content may cause slight swelling. For applications involving continuous chemical immersion, consult chemical compatibility charts specific to Nylon 66. Alternative insert materials (fluoropolymers, PEEK) provide superior chemical resistance where standard nylon is inadequate. Trojan's technical team can recommend appropriate materials for specific chemical environments.

27. Can nylon insert nuts be used in vacuum or space applications?

With specific considerations, yes. Vacuum environments pose two challenges: outgassing of volatile compounds from the nylon insert potentially contaminating sensitive equipment, and lack of atmospheric oxygen for thermal dissipation. Space-qualified fasteners typically require materials meeting NASA outgassing specifications (ASTM E595: <1.0% total mass loss, <0.1% collected volatile condensable material). Standard Nylon 66 may exceed these limits. For high-vacuum or space applications, specify vacuum-processed inserts or transition to all-metal locking nuts. Numerous spacecraft, satellites, and vacuum chambers successfully employ appropriately specified nylon insert nuts. Trojan can source space-qualified materials with appropriate certification for aerospace applications.

28. Do nylon insert nuts degrade from UV exposure?

Nylon 66 possesses inherent UV resistance superior to many polymers, but prolonged direct sunlight exposure over years causes gradual photo-oxidation. Surface embrittlement may occur, potentially reducing prevailing torque. However, since the insert resides inside the nut body, only the exposed inner surface contacts UV during storage or before installation. Once assembled, the insert is completely shielded from UV. Outdoor applications experience minimal UV degradation because the nut hex body shadows the insert. For maximum UV resistance in long-term outdoor storage, consider UV-stabilised nylon variants or store fasteners in enclosed containers. Practically, UV degradation rarely affects field performance of properly installed nylon insert nuts.

Section 5: Installation, Torque & Assembly

29. Can nylon insert nuts be installed with impact wrenches?

Not recommended for critical applications. Impact wrenches deliver high instantaneous torque through rapid hammering action, potentially damaging the nylon insert through shock loading or localised overheating from friction. The polymer insert can partially extrude, lose resilience, or develop stress cracks. For non-critical assemblies where controlled torque isn't specified, judicious use of low-power impact drivers may be acceptable - use the minimum impact power necessary and employ operator skill to avoid overtightening. Critical applications absolutely require controlled torque application using beam-type, dial-type, or electronic torque wrenches. Trojan recommends continuous-pull tightening for optimal insert life.

30. Do I need to use thread lubricant on nylon insert nuts?

Depends on the application. For most general industrial applications, no lubrication is required - the nylon insert provides sufficient anti-galling properties. However, specific circumstances warrant lubrication:

- Stainless steel applications (particularly austenitic grades prone to galling)

- High-strength fasteners with elevated installation torques

- Applications specifying precise clamp loads requiring consistent friction coefficients

- Torque-angle tightening procedures

When lubricant is used, torque specifications must be adjusted downward (typically 20-30% reduction) because lubrication reduces friction. Never apply lubricant unless assembly procedures explicitly specify it - doing so risks exceeding design clamp loads and potentially yielding threads. If specification requires lubrication, use products compatible with nylon (avoid chlorinated solvents).

31. What happens if I overtighten a nylon insert nut?

Overtightening produces several failure modes. Initially, excessive torque may extrude the nylon insert, forcing polymer material outward past the nut face or inward against the bolt threads, permanently deforming the insert and potentially reducing locking effectiveness. Continued overtightening can strip the internal threads of the nut, particularly in lower-strength materials or smaller thread sizes. Ultimate failure involves bolt tensile fracture or thread stripping. Even if catastrophic failure doesn't occur, overtightening induces residual stresses that accelerate fatigue crack initiation in cyclic loading. Always adhere to specified torque limits and use calibrated torque wrenches for critical assemblies.

32. How do I measure prevailing torque?

Prevailing torque measurement requires a calibrated torque wrench or torque meter. Two values are typically measured:

On-torque (running torque): Thread the nut onto a clean, undamaged bolt without seating it against any surface. Measure the torque required to rotate the nut continuously through the nylon insert region before the nut contacts the bearing surface. This represents pure locking torque.

Off-torque (break-away torque): After full assembly and subsequent loosening, measure the torque required to initiate nut rotation off the bearing surface. This includes both prevailing torque and any static friction from the seated joint.

Specifications establish minimum and maximum acceptable values. Trojan's quality processes include statistical sampling of prevailing torque for production lots, ensuring consistent locking performance.

33. Can nylon insert nuts be used with fine-pitch threads?

Absolutely - fine pitch threads are specifically addressed in standards BS EN ISO 7040, ISO 10511, and DIN 982. Fine pitch threads provide greater thread engagement per unit length, beneficial in thin-wall applications, hard materials, or where maximum strength is required. The nylon insert functions identically regardless of thread pitch. Fine pitch threads do require more precise manufacturing tolerances and careful handling to prevent cross-threading during installation. Trojan manufactures nylon insert nuts in coarse, fine, extra-fine, and speciality pitches across metric, Imperial, and Unified thread forms.

34. What is the minimum thread engagement length for nylon insert nuts?

Thread engagement length depends on material strength and loading conditions. For steel bolts into steel nuts, minimum engagement should equal 1.0 times the bolt diameter for Grade 8.8 materials (example: M10 requires 10mm minimum engagement). Lower-strength materials require proportionally more engagement. Since nylon insert nuts are typically taller than standard nuts, they inherently provide good thread engagement. However, ensure the bolt penetrates completely through the nylon insert region - the locking function requires thread contact with the polymer collar. Inadequate engagement reduces both strength and locking effectiveness. Trojan manufactures tall nylon insert nuts for applications requiring extended engagement.

35. Can nylon insert nuts be staked, crimped, or further secured?

Generally unnecessary and potentially detrimental. The nylon insert provides the primary locking mechanism - additional securing methods typically aren't required. Staking (punch marking the nut to deform metal into the bolt threads) or crimping risks damaging the nylon insert and may actually reduce locking effectiveness. If application requirements mandate absolutely no possibility of loosening (beyond what nylon inserts provide), consider all-metal lock nuts with post-installation crimping, castle nuts with cotter pins, or safety wiring. For extreme-vibration or safety-critical applications where redundant locking is desired, Nord-Lock washers or wedge-locking washers can supplement nylon insert nuts without interfering with the polymer insert.

Section 6: Reusability, Maintenance & Inspection

36. How many times can a nylon insert nut be reused?

No universal answer exists - reusability depends on multiple factors including insert design, material quality, installation conditions, service environment, and application severity. Laboratory testing of aerospace-grade nuts demonstrates 5-15 assembly cycles maintaining acceptable prevailing torque under ideal conditions (room temperature, clean threads, no preload between tests). Real-world service introduces additional variables: thermal cycling, chemical exposure, time-dependent creep, and invisible damage. Conservative practice limits reuse to 3-5 cycles maximum, and only for non-critical applications after prevailing torque verification. Trojan categorically recommends single-use for safety-critical applications - the modest replacement cost is insignificant compared to failure consequences.

37. How do I know if a used nylon insert nut is still good?

Several inspection criteria indicate serviceability:

Visual inspection:

- No visible nylon extrusion beyond nut face

- No discolouration, burning, or melting of polymer

- No cracks in nut hex body

- No thread damage, galling, or cross-threading

- No contamination embedded in insert

Functional testing:

- Measured prevailing torque within specification limits

- Nut threads smoothly without binding or catching

- Insert remains firmly retained in nut body

Service history:

- Known temperature exposure within limits

- Documented installation/removal cycles

- No known chemical exposure

- Reasonable service duration

If any doubt exists about nut condition, replace it. Never compromise safety for marginal cost savings.

38. What reduces the life of a nylon insert nut?

Multiple degradation mechanisms shorten service life:

- Elevated temperatures accelerating polymer aging

- Repeated installation/removal cycles causing mechanical wear

- Chemical exposure (solvents, aggressive fluids) attacking polymer

- UV radiation (outdoor storage) causing surface embrittlement

- Moisture absorption affecting dimensional stability

- Overtightening causing compressive set or insert extrusion

- Thread damage reducing locking contact area

- Contamination interfering with thread engagement

- Time-dependent creep under sustained load

Minimising these factors maximises nut life. Store fasteners in controlled environments, handle carefully during installation, and replace according to maintenance schedules rather than waiting for evident failure.

39. Can I clean and reuse nylon insert nuts removed during maintenance?

For non-critical applications, yes, provided they pass inspection criteria. Clean threads thoroughly with solvent (avoid chlorinated solvents that attack nylon - use mineral spirits or isopropanol), blow dry with compressed air, and visually inspect per previous guidelines. Measure prevailing torque on a clean bolt - if values fall within specification, cautious reuse in non-critical locations may be acceptable. However, unknowns regarding service history make this practice questionable. Many organisations maintain policies prohibiting fastener reuse regardless of apparent condition. Economic analysis often favours replacement - technician time for inspection and testing exceeds new fastener cost.

40. Do nylon insert nuts require periodic inspection or replacement schedules?

Maintenance-critical applications (aircraft, rail vehicles, elevators, pressure vessels, lifting equipment) typically mandate scheduled fastener inspection as part of preventive maintenance programmes. These schedules derive from manufacturer recommendations, regulatory requirements, operational experience, and risk assessment. Inspection may involve:

- Visual examination for damage or deterioration

- Torque verification (measurement and retightening if necessary)

- Scheduled replacement at defined intervals or utilisation cycles

- Non-destructive testing (NDT) of bolts and studs

- Documentation and traceability

Non-critical applications rarely require scheduled fastener maintenance beyond opportunistic inspection during other maintenance activities. For critical applications, consult OEM recommendations, regulatory authorities (CAA, FRA, HSE), and qualified engineering judgment to establish appropriate inspection intervals.

Section 7: Design Considerations & Engineering

41. When should I use a thin (low-profile) nylon insert nut?

Thin nylon insert nuts serve applications with restricted axial clearance where standard-height nuts cannot fit. Common scenarios include:

- Limited thread engagement length on studs or tapped holes

- Tight clearance to adjacent components

- Sheet metal assemblies where nut height matters

- Weight-reduction requirements

- Aesthetic considerations requiring low profile

Trade-offs include reduced thread engagement (lower strength) and potentially reduced locking effectiveness from shallower insert depth. Standards ISO 10512 (coarse) and ISO 10511 (fine) specify thin nut dimensions. Despite reduced height, thin nylon insert nuts still provide reliable locking for appropriate applications. Trojan manufactures thin profile nuts across comprehensive size ranges.

42. What are the advantages of nylon insert flange nuts?

Flange nuts integrate a wide washer-like bearing surface with the nut body, providing multiple benefits:

- Increased bearing area reducing surface pressure

- Elimination of separate washer (part count reduction)

- Prevention of washer loss or incorrect installation

- Better load distribution over soft materials (composites, plastics)

- Resistance to embedment into joint surfaces

- Enhanced vibration resistance from larger contact patch

Nylon insert flange nuts combine locking and load distribution in a single component, ideal for vibration-prone assemblies in soft materials. Automotive, aerospace, and consumer products extensively employ this design. Trojan manufactures serrated and non-serrated flange variants.

43. Can nylon insert nuts be used in tapped holes?

Yes, but with important limitations. When threading a nylon insert nut into a tapped hole (rather than onto a bolt), ensure adequate thread engagement depth - the hole must be deep enough to allow the nut to thread completely through the insert region plus additional engagement for strength. The through-hole must provide clearance for a wrench to install the nut. Blind tapped holes present challenges because the nut cannot bottom out, potentially leaving inadequate thread engagement. This application is relatively uncommon - typically, bolts thread into tapped holes whilst nuts go onto external threads. If your design requires nuts in tapped holes, verify sufficient depth and engagement.

44. What is the weight difference between nylon insert nuts and standard nuts?

Minimal - the nylon insert represents only 2-5% of total nut weight depending on size. For example, an M10 steel nylon insert nut weighs approximately 12-14 grams versus 12-13 grams for an equivalent plain hexagon nut. The weight increase is negligible in most applications. For extreme weight-sensitive applications (aerospace, racing, drones), consider:

- Aluminium nylon insert nuts (40-60% weight reduction versus steel)

- Thin-profile designs

- Optimised nut geometry (reduced hex body thickness where permitted)

Weight savings from material substitution dramatically exceed any difference attributable to the nylon insert itself.

45. Are left-hand thread nylon insert nuts available?

Yes. Left-hand threads (reverse helix, loosening with clockwise rotation) serve applications where conventional right-hand threads would self-loosen due to rotational direction of the assembly. Common applications include:

- Left-side bicycle pedals

- Angle grinder backing nuts

- Rotating shafts and arbours

- Certain propeller fasteners

- Mixer and blender components

Trojan manufactures left-hand nylon insert nuts across metric, Imperial, and Unified threads in standard and special sizes. The nylon insert functions identically regardless of helix direction. Left-hand nuts are typically marked with grooves or "LH" stamps to prevent installation errors.

46. Can nylon insert nuts be made in custom sizes or geometries?

Absolutely. Trojan specialises in special and non-standard fastener manufacturing. We routinely produce:

- Non-preferred thread sizes and pitches

- Oversize threads for thread repair

- Custom across-flats dimensions

- Increased or reduced nut height

- Modified insert depth or position

- Dual-thread nuts (left-hand one end, right-hand other)

- Custom materials and coatings

- Precision-tolerance variants

- Modified geometries for specialised applications

Provide drawings, specifications, or samples - our engineering team will evaluate manufacturability and recommend optimal production approaches. Minimum order quantities for custom sizes vary based on complexity but are often lower than anticipated.

47. What is the difference between a nylon insert nut and a centre-lock nut?

Centre-lock nuts employ a different locking mechanism - a crimped or deformed section in the nut body creates an out-of-round condition that binds against bolt threads. All-metal construction enables higher temperature capability (typically 300-400°C) but generally provides less consistent locking torque than nylon inserts. Centre-lock nuts are typically single-use because the metal deformation doesn't recover. Nylon insert nuts offer more reliable, quantifiable locking performance with limited reusability. Choose centre-lock all-metal nuts for high-temperature applications; choose nylon insert nuts for general applications requiring consistent prevailing torque and potential reuse.

Section 8: Quality, Testing & Specifications

48. What quality certifications do Trojan's nylon insert nuts carry?

Trojan Special Fasteners maintains comprehensive quality management systems and can provide:

- Material certificates (EN 10204 3.1 or 3.2)

- Dimensional inspection reports

- Prevailing torque test results (on application and first removal)

- Proof load test documentation by independent laboratories

- Hardness test results (in-house)

- Traceability to lot numbers

- Compliance certifications to specific standards

- First Article Inspection Reports (FAIR) for aerospace

- RoHS and REACH declarations

- CBAM (Carbon Border Adjustment Mechanism) figures for your exports

Our quality processes ensure every nut meets specification requirements with full documentation supporting critical applications. Please ensure you speak with Trojan Special Fasteners and advise them which documentation you will need.

49. How is prevailing torque tested during manufacturing?

Trojan employs statistical sampling protocols testing prevailing torque on calibrated test equipment. Sample nuts from each production lot thread onto precision test mandrels (hardened, ground bolts with verified thread dimensions) mounted in torque meters. The operator rotates the nut through the insert region at controlled speed whilst the meter records running torque. Results must fall within specification limits (typically expressed as minimum and maximum values in Newton-metres). Out-of-specification results trigger investigation and potential lot rejection. This testing ensures consistent locking performance across all supplied fasteners.

50. What is proof load testing?

Proof load testing verifies nut strength by threading the nut onto a hardened mandrel and applying the specified tensile load in a calibrated testing machine. The nut must withstand this load (typically 90% of minimum thread stripping strength) for a specified duration without thread failure or permanent deformation. After load removal, the nut must still thread smoothly on a standard gauge. This destructive test is performed on samples from each production lot, verifying material strength and thread quality meet specification requirements. Proof loads are tabulated in standards for each thread size and grade.

Section 9: Comparison with Other Locking Methods

51. Are nylon insert nuts better than thread-locking adhesives?

Different approaches with distinct advantages. Nylon insert nuts provide immediate locking (no cure time), are reusable (limited cycles), require no surface preparation, work across temperature ranges from -55°C to +120°C, and function reliably in contaminated or oily environments. Thread-locking adhesives (Loctite, etc.) offer variable strength grades, higher temperature resistance (up to 230°C for high-temp formulations), complete thread engagement, and ability to seal threads against leakage. However, adhesives require clean, dry, oil-free surfaces, cure time before achieving full strength, and are essentially permanent (requiring heat for disassembly). Choose nylon insert nuts for field maintenance, rapid assembly, or reusable applications; choose adhesives for permanent assemblies or higher temperatures.

52. How do nylon insert nuts compare to distorted thread lock nuts?

All-metal distorted thread lock nuts employ deformed or out-of-round threads creating interference without polymer inserts. Advantages include extreme temperature capability (600°C+), no polymer degradation concerns, and applicability in radiation, vacuum, or chemical environments hostile to plastics. However, distorted thread nuts typically provide less consistent locking torque, may be single-use (some designs permanently deform), and cost more than nylon insert nuts. Nylon insert nuts dominate general industrial applications (temperature <120°C) due to superior performance-to-cost ratio. All-metal nuts serve high-temperature, chemical, or radiation environments where polymers cannot survive.

53. Can I use a regular lock washer instead of a nylon insert nut?

Technically yes, practically no. Extensive testing (including German Junker vibration tests) demonstrates split lock washers and spring washers provide marginal vibration resistance - they prevent loosening primarily through spring tension maintenance, which diminishes as the washer sets. Nylon insert nuts create continuous frictional interference preventing rotation even after joint relaxation. Studies show conventional lock washers often perform no better than plain washers in vibration tests. For critical applications requiring reliable anti-loosening performance, nylon insert nuts, adhesives, or positive locking methods (cotter pins, safety wire) are categorically superior. Lock washers persist mainly through historical inertia rather than engineering merit.

54. What about Nord-Lock washers versus nylon insert nuts?

Nord-Lock washers employ wedge-locking technology - pairs of washers with cam faces and radial teeth create a secure mechanical interlock. Advantages include extreme temperature capability, immunity to vibration, unlimited reusability, and no polymer degradation. They excel in structural steel, heavy equipment, and high-temperature applications. Disadvantages include higher cost (typically 5-10 times nylon insert nuts), requirement for matched pairs, and greater assembly complexity. For most general applications, nylon insert nuts provide excellent performance at lower cost. For extreme conditions (high temperature, severe vibration, critical structural joints), Nord-Lock or equivalent wedge-locking systems justify premium investment.

Section 10: Purchasing, Specification & Technical Support

55. How do I specify the correct nylon insert nut for my application?

Provide the following information to Trojan's technical team:

- Thread size and type (M10 x 1.5, 1/2"-13 UNC, etc.)

- Standard or specification (ISO 7042, MS17825, etc.)

- Material and grade (steel Grade 8, A4-70 stainless, etc.)

- Surface finish (zinc plated, passivated, galvanised, etc.)

- Nut style (standard, thin, flange)

- Special requirements (left-hand thread, oversize, etc.)

- Quantity required

- Application description (environment, temperature, criticality)